Replacing Broken Pieces in Copper Foil Panels

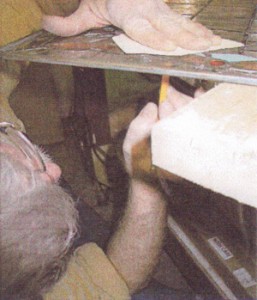

Step 1. Support the panel on blocks to allow solder to melt away. Use two soldering irons to provide plenty of heat over a long stretch of solder seam.

Step 1. Support the panel on blocks to allow solder to melt away. Use two soldering irons to provide plenty of heat over a long stretch of solder seam.

Step 2. The underside will be rough, so make your pattern by holding the manila stock on top and outlining from below with a sharp pencil.

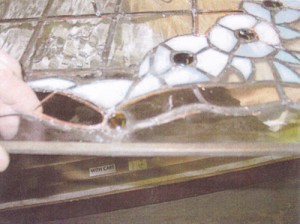

Step 3. Grind the new piece to a close fit, and after wrapping it with copper foil, solder it in place. Finish the top side first; the bottom will be a rougher-looking job when you first turn it over, but easier to solder if you’ve completed the top side first.

Additional tips’

- It helps to start by applying flux and re-melting the whole solder seam around the piece to be replaced. Do this especially if the piece had been finished with patina. This makes the later melting-out easier.

- Larger pieces of glass may be crisscrossed with scorelines from your glass cutter and shattered by tapping from the other side to fragment the glass to be removed into smaller pieces which are easier to remove.

- If you do this, be sure to protect your eyes, and have a shop-vac or bench brush handy to keep fragments cleared away.

- Don’t tap so hard that you break adjacent pieces of glass.

- When peeling out the old foil around the now-missing piece, the trick is not to disturb the foil on the adjacent pieces. Use a stainless steel tweezers or forceps if you can, because solder will not stick to it.