Ventilating Soldering Fumes

What is soldering flux? Soldering Fluxes are usually water solutions of Acids, Chlorine compounds or Ammonia compounds that when heated by the soldering iron, act as reducing agents.

Why do we need it? Almost all metals are tarnished (oxidized) by the air they are exposed to, making them impossible to solder with just heat alone. The purpose of the flux is to scavenge Oxygen from the surface of the metal being soldered, removing the tarnish and making a chemical bond possible between the base metal and the solder.

What is in the fumes? Among other things, Chlorine, chloride compounds, and Ammonia, as well as steam contaminated by heavy metals. It’s nothing that you want to breathe. Short term effects of flux exposure include runny nose, sore throat, irritated eyes, and headaches. Long term effects are more serious. A ventilation system of some sort is really necessary.

Ready-to-use Systems for off-the-shelf purchase include the Inland Fume Trap and the Hakko Smoke Absorber. Both are small 115 volt table top units that include a fan and a filter in a small box that can be placed right next to, or even on top of, your work. They work by drawing contaminated air through a gauze or sponge made of activated charcoal, which absorbs harmful compounds. Either system is effective, but the manufacturer’s claims of protecting 20 square feet of workbench are badly exaggerated. We recommend that you count on only two square feet right in front of the box to be truly cleaned. One thing we think that the manufacturers don’t stress enough is the need to change the filter frequently. Conservatively, you should count on about twenty hours’ useful life for each filter. Activated charcoal is likely to absorb any kind of smoke, vapor or indoor air contaminants, even if the fan motor is not running. For people who use the machine only occasionally, we suggest taking the filter out and putting it in a zip-loc bag in your freezer. The low temperature will slow the chemical activity and prolong the life of the filter. You can also record on the outside of the bag the amounts of time the filter is used, so you’ll know when to replace it.

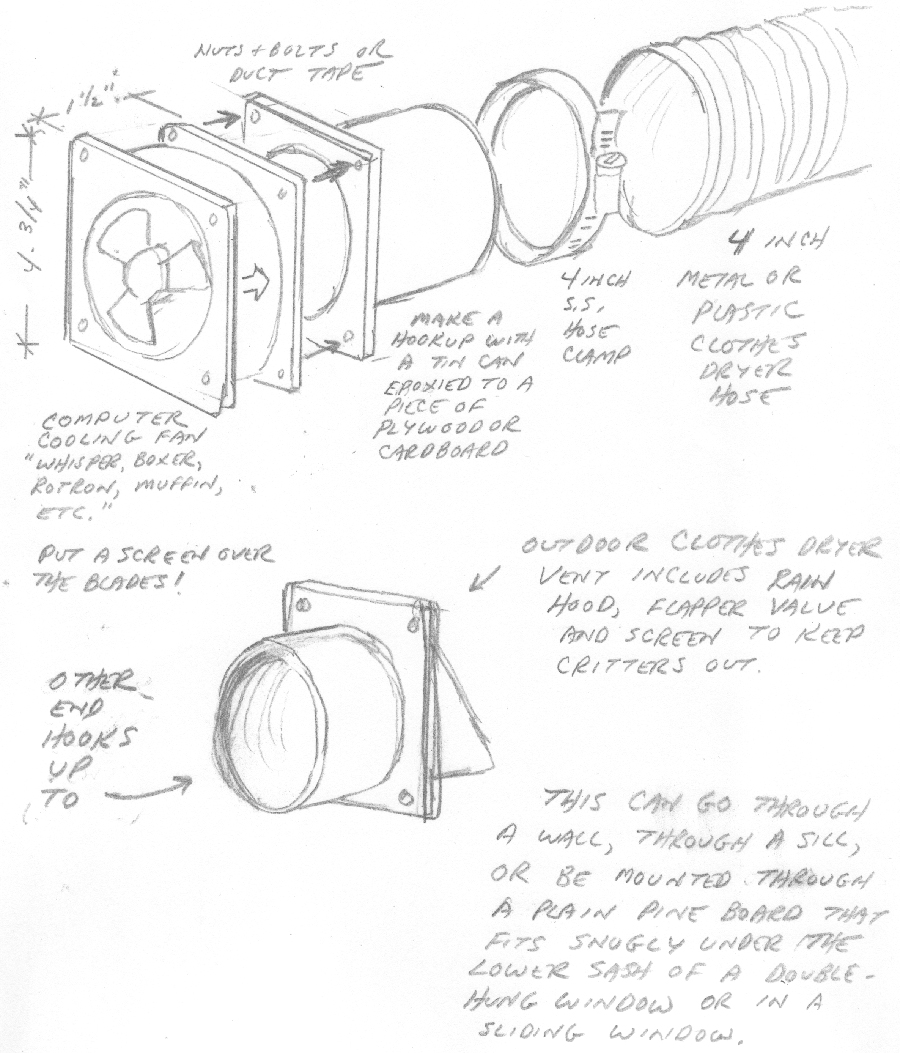

Venting to outdoors is a better system. Useful components are electronic cooling fans (the best ones are rated 60 to 80 cubic feet per minute, or “cfm”), 4″ clothes dryer hose and 4″ exterior clothes dryer vents, stainless steel worm-screw driven hose clamps, coffee cans, and good old duct tape.